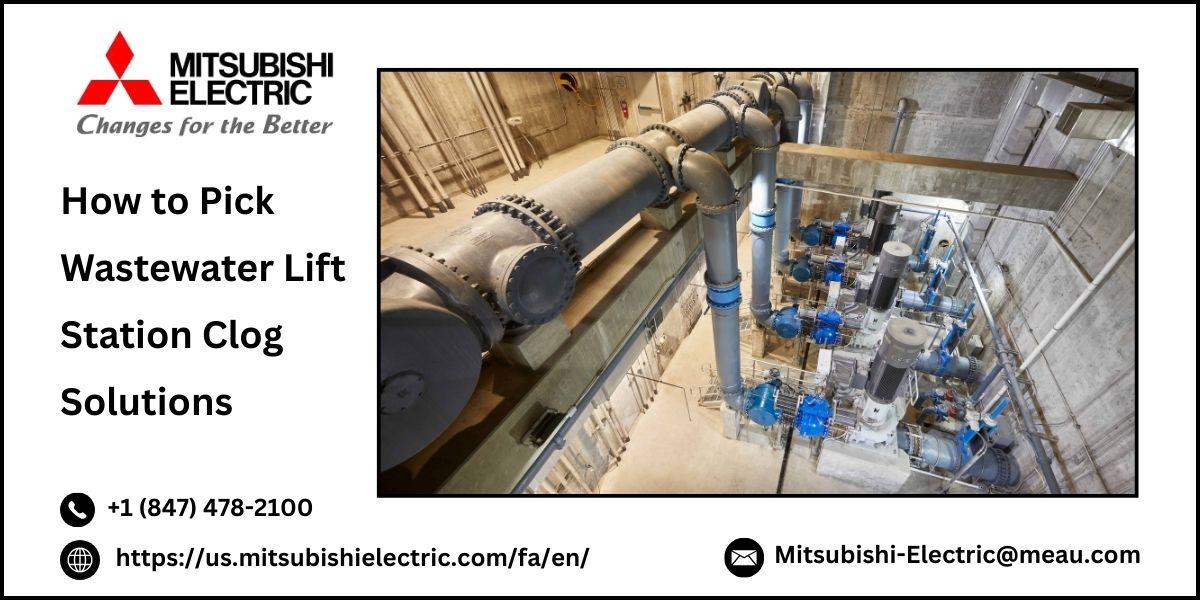

How to Pick Wastewater Lift Station Clog Solutions

The proper selection of wastewater lift station clog solutions contributes to avoiding out-of-service periods, expensive maintenance, and overflowing systems. The initial one is to determine the most widespread causes of clogs, including wipes, fats, oils, grease, and debris. Knowledge of the cause assists in identifying the most appropriate wastewater lift station clog solutions, be it mechanical, hydraulic or preventive.

The modernization of pumps is frequently one of the strategies. The chopper pumps, vortex impellers and screw-type pumps are specifically designed to handle solids that do not plug. The use of wet-well design modification and enhancement of screening and grinding equipment can offer effective solutions to wastewater lift station clogs in some instances, without the necessity to replace the key components. Automated monitoring systems have the advantage that operators are alerted to abnormal pump behavior and this minimizes the chances of unforeseen failures.

Routine servicing is also very important. Wet wells should be cleaned, pump settings should be adjusted, necessary velocities of a flow should be maintained; all this contributes to the prevention of risks of clogging. The small problems can be transformed to major problems by training the staff on how to identify early warning signs. The utilities can maintain a reliable and efficient operation of lift stations at low operational costs and the need to respond in cases of emergency by ensuring that the right equipment, preventive measures, and the operational best practices are combined.

Read More: https://differ.blog/p/how-to-pick-wastewater-lift-station-clog-solutions-b52678

#wastewaterliftstationclogsolutions #wastewaterliftstation

The proper selection of wastewater lift station clog solutions contributes to avoiding out-of-service periods, expensive maintenance, and overflowing systems. The initial one is to determine the most widespread causes of clogs, including wipes, fats, oils, grease, and debris. Knowledge of the cause assists in identifying the most appropriate wastewater lift station clog solutions, be it mechanical, hydraulic or preventive.

The modernization of pumps is frequently one of the strategies. The chopper pumps, vortex impellers and screw-type pumps are specifically designed to handle solids that do not plug. The use of wet-well design modification and enhancement of screening and grinding equipment can offer effective solutions to wastewater lift station clogs in some instances, without the necessity to replace the key components. Automated monitoring systems have the advantage that operators are alerted to abnormal pump behavior and this minimizes the chances of unforeseen failures.

Routine servicing is also very important. Wet wells should be cleaned, pump settings should be adjusted, necessary velocities of a flow should be maintained; all this contributes to the prevention of risks of clogging. The small problems can be transformed to major problems by training the staff on how to identify early warning signs. The utilities can maintain a reliable and efficient operation of lift stations at low operational costs and the need to respond in cases of emergency by ensuring that the right equipment, preventive measures, and the operational best practices are combined.

Read More: https://differ.blog/p/how-to-pick-wastewater-lift-station-clog-solutions-b52678

#wastewaterliftstationclogsolutions #wastewaterliftstation

How to Pick Wastewater Lift Station Clog Solutions

The proper selection of wastewater lift station clog solutions contributes to avoiding out-of-service periods, expensive maintenance, and overflowing systems. The initial one is to determine the most widespread causes of clogs, including wipes, fats, oils, grease, and debris. Knowledge of the cause assists in identifying the most appropriate wastewater lift station clog solutions, be it mechanical, hydraulic or preventive.

The modernization of pumps is frequently one of the strategies. The chopper pumps, vortex impellers and screw-type pumps are specifically designed to handle solids that do not plug. The use of wet-well design modification and enhancement of screening and grinding equipment can offer effective solutions to wastewater lift station clogs in some instances, without the necessity to replace the key components. Automated monitoring systems have the advantage that operators are alerted to abnormal pump behavior and this minimizes the chances of unforeseen failures.

Routine servicing is also very important. Wet wells should be cleaned, pump settings should be adjusted, necessary velocities of a flow should be maintained; all this contributes to the prevention of risks of clogging. The small problems can be transformed to major problems by training the staff on how to identify early warning signs. The utilities can maintain a reliable and efficient operation of lift stations at low operational costs and the need to respond in cases of emergency by ensuring that the right equipment, preventive measures, and the operational best practices are combined.

Read More: https://differ.blog/p/how-to-pick-wastewater-lift-station-clog-solutions-b52678

#wastewaterliftstationclogsolutions #wastewaterliftstation