Mitsubishi Electric is emerging as a marketing leader in innovative automation solutions. We provide the right guidance to a wide array of industries to boost their operational efficiency. Enhance your production and reduce your expenses by incorporating reliable industrial automation solutions. We understand the needs of business owners and manufacturers across the globe and our automation control solutions help them to meet their needs in the best way possible.

- 10 Posts

- 6 Photos

- 0 Videos

- Mitsubishi Electric Factory Automation at Vernon Hills, Illinois

- Lives in Vernon Hills

- From Vernon Hills

- Followed by 1 people

Recent Updates

- Tips on How To Reduce Energy Use in Data Centers

It is necessary to know how to minimize the amount of energy used in data centers to reduce the cost of operation and help in achieving sustainability. Optimization of cooling systems, which tend to be the biggest energy consumers is one of the effective ways. The study of the ways to save energy in data centers by managing airflows, hot-aisles/cold-aisles configurations, and using effective HVAC systems, can bring significant savings. The other option is to upgrade to efficient servers and use virtualization so that hardware requirements can be reduced. Power usage monitoring is also used to determine ways to cut down on power consumption in data centers, by focusing on the areas of inefficiency. Lastly, the use of renewable energy sources and automation in workload distribution is another way of how to minimize energy consumption in the data center with the subsequent increase of overall performance.

Read More: https://mitsubishielectricautomation.notion.site/Tips-on-How-To-Reduce-Energy-Use-in-Data-Centers-2c6e092eed2d80a38b2dc6066699642cTips on How To Reduce Energy Use in Data Centers It is necessary to know how to minimize the amount of energy used in data centers to reduce the cost of operation and help in achieving sustainability. Optimization of cooling systems, which tend to be the biggest energy consumers is one of the effective ways. The study of the ways to save energy in data centers by managing airflows, hot-aisles/cold-aisles configurations, and using effective HVAC systems, can bring significant savings. The other option is to upgrade to efficient servers and use virtualization so that hardware requirements can be reduced. Power usage monitoring is also used to determine ways to cut down on power consumption in data centers, by focusing on the areas of inefficiency. Lastly, the use of renewable energy sources and automation in workload distribution is another way of how to minimize energy consumption in the data center with the subsequent increase of overall performance. Read More: https://mitsubishielectricautomation.notion.site/Tips-on-How-To-Reduce-Energy-Use-in-Data-Centers-2c6e092eed2d80a38b2dc6066699642c0 Comments 0 Shares1 Please log in to like, share and comment!

Please log in to like, share and comment! - Why Wastewater Lift Station IoT Sensors Are Essential Today

Wastewater Lift Station IoT Sensors are transforming the management of the infrastructural system of utilities. As the communities and systems evolve, real-time monitoring has become a valuable instrument to prevent failures and costly crises. The IoT sensor Wastewater Lift Station provides real-time data regarding the condition of the pumps, the volume of the flow, and the condition of the equipment and makes sure that the operators are able to identify a possible issue in time and improve the state of the device. This improves dependability, reduces downtime and extends the lifespan of the important assets. Furthermore, Wastewater Lift Station IoT Sensors also help in predictive maintenance and allow the utilities to prevent reactive maintenance and begin to make smarter, more data-driven decisions. The fact that they can be automated and connected to cloud-based systems is what makes these sensors efficient in operations, as well as reduce the need of having to visit the location physically. Lastly, the presence of Wastewater Lift Station IoT Sensors would enhance safer and sustainable wastewater management by lowering the expenses of operating the services, as well as, increasing the reliability of the provided services to the communities.

Read More: https://differ.blog/p/why-wastewater-lift-station-iot-sensors-are-essential-today-5b5935

#wastewaterliftstationiotsensors #wastewaterliftstationupgrades #wastewaterliftstationreportingWhy Wastewater Lift Station IoT Sensors Are Essential Today Wastewater Lift Station IoT Sensors are transforming the management of the infrastructural system of utilities. As the communities and systems evolve, real-time monitoring has become a valuable instrument to prevent failures and costly crises. The IoT sensor Wastewater Lift Station provides real-time data regarding the condition of the pumps, the volume of the flow, and the condition of the equipment and makes sure that the operators are able to identify a possible issue in time and improve the state of the device. This improves dependability, reduces downtime and extends the lifespan of the important assets. Furthermore, Wastewater Lift Station IoT Sensors also help in predictive maintenance and allow the utilities to prevent reactive maintenance and begin to make smarter, more data-driven decisions. The fact that they can be automated and connected to cloud-based systems is what makes these sensors efficient in operations, as well as reduce the need of having to visit the location physically. Lastly, the presence of Wastewater Lift Station IoT Sensors would enhance safer and sustainable wastewater management by lowering the expenses of operating the services, as well as, increasing the reliability of the provided services to the communities. Read More: https://differ.blog/p/why-wastewater-lift-station-iot-sensors-are-essential-today-5b5935 #wastewaterliftstationiotsensors #wastewaterliftstationupgrades #wastewaterliftstationreporting0 Comments 0 Shares1

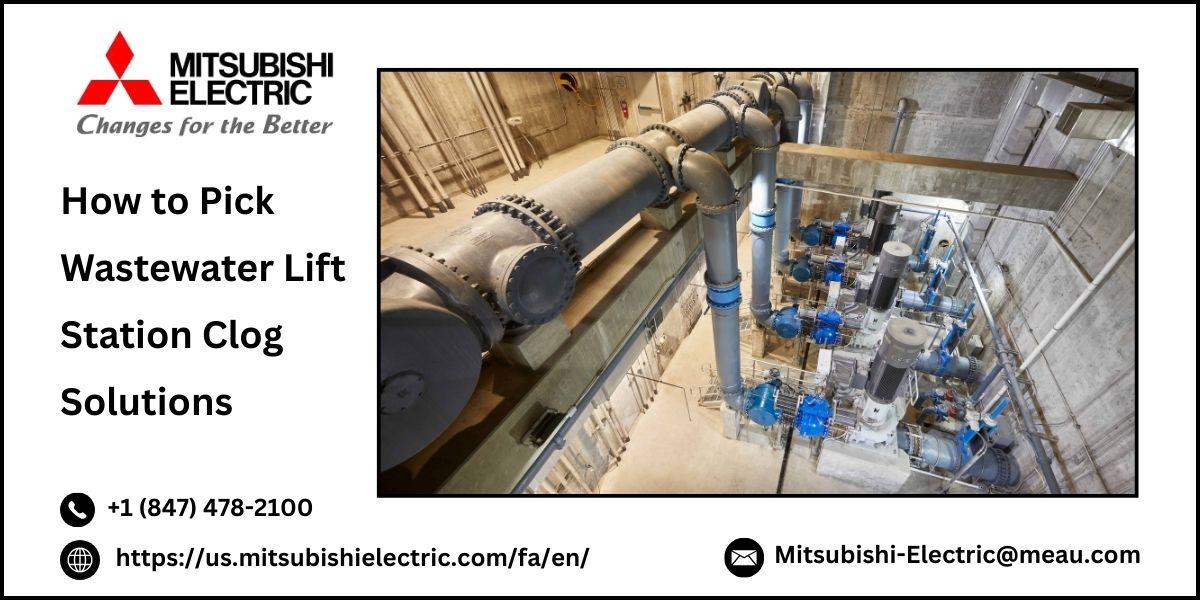

- How to Pick Wastewater Lift Station Clog Solutions

The proper selection of wastewater lift station clog solutions contributes to avoiding out-of-service periods, expensive maintenance, and overflowing systems. The initial one is to determine the most widespread causes of clogs, including wipes, fats, oils, grease, and debris. Knowledge of the cause assists in identifying the most appropriate wastewater lift station clog solutions, be it mechanical, hydraulic or preventive.

The modernization of pumps is frequently one of the strategies. The chopper pumps, vortex impellers and screw-type pumps are specifically designed to handle solids that do not plug. The use of wet-well design modification and enhancement of screening and grinding equipment can offer effective solutions to wastewater lift station clogs in some instances, without the necessity to replace the key components. Automated monitoring systems have the advantage that operators are alerted to abnormal pump behavior and this minimizes the chances of unforeseen failures.

Routine servicing is also very important. Wet wells should be cleaned, pump settings should be adjusted, necessary velocities of a flow should be maintained; all this contributes to the prevention of risks of clogging. The small problems can be transformed to major problems by training the staff on how to identify early warning signs. The utilities can maintain a reliable and efficient operation of lift stations at low operational costs and the need to respond in cases of emergency by ensuring that the right equipment, preventive measures, and the operational best practices are combined.

Read More: https://differ.blog/p/how-to-pick-wastewater-lift-station-clog-solutions-b52678

#wastewaterliftstationclogsolutions #wastewaterliftstationHow to Pick Wastewater Lift Station Clog Solutions The proper selection of wastewater lift station clog solutions contributes to avoiding out-of-service periods, expensive maintenance, and overflowing systems. The initial one is to determine the most widespread causes of clogs, including wipes, fats, oils, grease, and debris. Knowledge of the cause assists in identifying the most appropriate wastewater lift station clog solutions, be it mechanical, hydraulic or preventive. The modernization of pumps is frequently one of the strategies. The chopper pumps, vortex impellers and screw-type pumps are specifically designed to handle solids that do not plug. The use of wet-well design modification and enhancement of screening and grinding equipment can offer effective solutions to wastewater lift station clogs in some instances, without the necessity to replace the key components. Automated monitoring systems have the advantage that operators are alerted to abnormal pump behavior and this minimizes the chances of unforeseen failures. Routine servicing is also very important. Wet wells should be cleaned, pump settings should be adjusted, necessary velocities of a flow should be maintained; all this contributes to the prevention of risks of clogging. The small problems can be transformed to major problems by training the staff on how to identify early warning signs. The utilities can maintain a reliable and efficient operation of lift stations at low operational costs and the need to respond in cases of emergency by ensuring that the right equipment, preventive measures, and the operational best practices are combined. Read More: https://differ.blog/p/how-to-pick-wastewater-lift-station-clog-solutions-b52678 #wastewaterliftstationclogsolutions #wastewaterliftstation0 Comments 0 Shares1

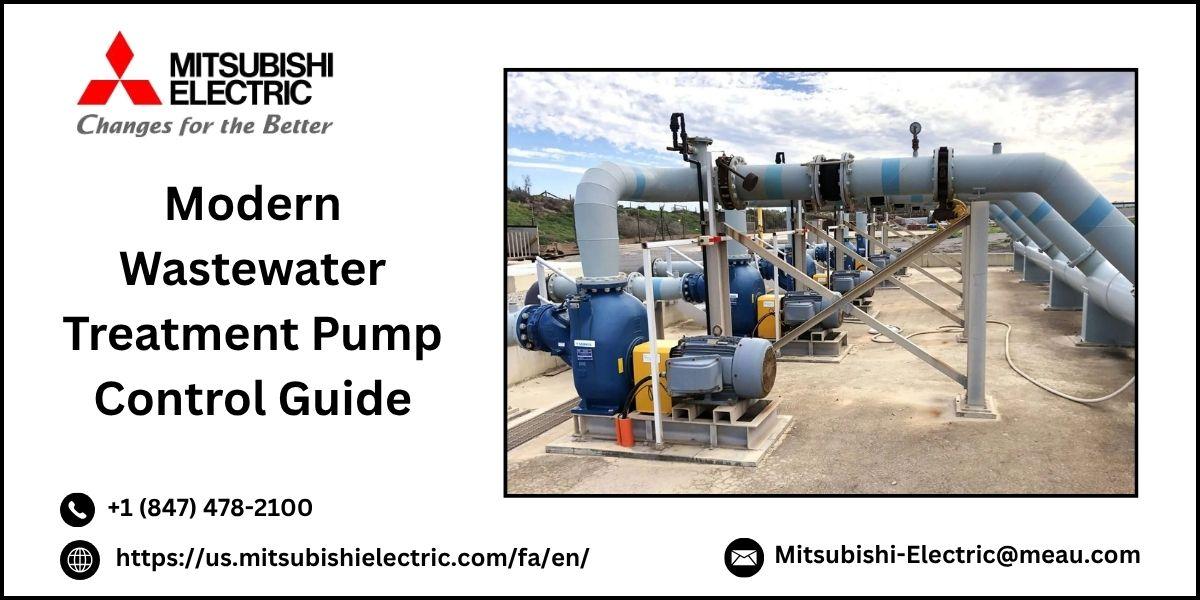

- Modern Wastewater Treatment Pump Control Guide

The Modern Wastewater Treatment Pump Control Guide is aimed at assisting operators to enhance their efficiency, reliability, and energy use in all wastewater treatment phases. With the development of the facilities, a new era of wastewater treatment requires smarter systems, and this guide shows that pump control is a key part of the intended change.

The pumps in modern wastewater treatment ensure that the water, sludge and chemicals are moved accurately. Good pump control allows flow levels to be maintained, equipment is less stressed, and energy savings can be made. The current pump control guide focuses on the significance of variable-frequency drives, intelligent sensors and automated reasoning to ensure the optimum performance of the pump in any given condition.

Real-time monitoring of the state of the plants is necessary to identify wear, avoid failures, and provide the smooth operation of the modern plants. Underdeveloped pump control strategies allow operators to modify speeds, balance loads and cut unnecessary power use. This is a contemporary wastewater treatment pump controller manual that also describes the scope of predictive analytics to increase the pump life and reduce maintenance expenses.

Security and regulations are of high concern. The stable control of pumps will avoid any overflows, stability in the standards of regulations, and stability in the wastewater treatments.

In general, this Modern Wastewater Treatment Pump Control Guide offers viable information in maximizing the efficiency, enhancing reliability, and serving the next generation of the modern wastewater treatment processes.

Read More: https://differ.blog/p/modern-wastewater-treatment-pump-control-guide-e0528dModern Wastewater Treatment Pump Control Guide The Modern Wastewater Treatment Pump Control Guide is aimed at assisting operators to enhance their efficiency, reliability, and energy use in all wastewater treatment phases. With the development of the facilities, a new era of wastewater treatment requires smarter systems, and this guide shows that pump control is a key part of the intended change. The pumps in modern wastewater treatment ensure that the water, sludge and chemicals are moved accurately. Good pump control allows flow levels to be maintained, equipment is less stressed, and energy savings can be made. The current pump control guide focuses on the significance of variable-frequency drives, intelligent sensors and automated reasoning to ensure the optimum performance of the pump in any given condition. Real-time monitoring of the state of the plants is necessary to identify wear, avoid failures, and provide the smooth operation of the modern plants. Underdeveloped pump control strategies allow operators to modify speeds, balance loads and cut unnecessary power use. This is a contemporary wastewater treatment pump controller manual that also describes the scope of predictive analytics to increase the pump life and reduce maintenance expenses. Security and regulations are of high concern. The stable control of pumps will avoid any overflows, stability in the standards of regulations, and stability in the wastewater treatments. In general, this Modern Wastewater Treatment Pump Control Guide offers viable information in maximizing the efficiency, enhancing reliability, and serving the next generation of the modern wastewater treatment processes. Read More: https://differ.blog/p/modern-wastewater-treatment-pump-control-guide-e0528d0 Comments 0 Shares1

- Reasons Why Industries Are Adopting Automated Line Robots

Automated line robots are becoming increasingly popular in industries around the world as the industries aim at achieving more efficiency, reliability and competitiveness. The contemporary manufacturing processes require precision and stable production, and human beings cannot be as precise as robots in their repetitive tasks in the long term. With the growing demands and increasing product standards, customers are getting stricter in the demands related to automation, the company is trying to automate as much as possible, to reduce mistakes and enhance uniformity and a way of guaranteeing that all products can match the quality requirements of the customers.

Read More: https://medium.com/@mitsubishielectricautomation/reasons-why-industries-are-adopting-automated-line-robots-05190d386dda

#liftingautomatedrobots #automatedlinerobots #logisticsautomationtechnologyReasons Why Industries Are Adopting Automated Line Robots Automated line robots are becoming increasingly popular in industries around the world as the industries aim at achieving more efficiency, reliability and competitiveness. The contemporary manufacturing processes require precision and stable production, and human beings cannot be as precise as robots in their repetitive tasks in the long term. With the growing demands and increasing product standards, customers are getting stricter in the demands related to automation, the company is trying to automate as much as possible, to reduce mistakes and enhance uniformity and a way of guaranteeing that all products can match the quality requirements of the customers. Read More: https://medium.com/@mitsubishielectricautomation/reasons-why-industries-are-adopting-automated-line-robots-05190d386dda #liftingautomatedrobots #automatedlinerobots #logisticsautomationtechnology0 Comments 0 Shares1

- Ideas to Get Reliable Wastewater Lift Station Clog Solutions

Identify the proper and efficient wastewater lift station lift block remedies through a smart and automated pump framework and enhanced monitoring. Discover how predictive maintenance and new technology might stop blockages, reduce downtime, and enhance efficiency of the system in the long-term performance. Maintain your wastewater systems in an environmentally friendly manner.

Read more: https://mitsubishielectricautomation.notion.site/Ideas-to-Get-Reliable-Wastewater-Lift-Station-Clog-Solutions-29ce092eed2d80c48805db97de7af628

#LiftStationSolutions #WastewaterManagementIdeas to Get Reliable Wastewater Lift Station Clog Solutions Identify the proper and efficient wastewater lift station lift block remedies through a smart and automated pump framework and enhanced monitoring. Discover how predictive maintenance and new technology might stop blockages, reduce downtime, and enhance efficiency of the system in the long-term performance. Maintain your wastewater systems in an environmentally friendly manner. Read more: https://mitsubishielectricautomation.notion.site/Ideas-to-Get-Reliable-Wastewater-Lift-Station-Clog-Solutions-29ce092eed2d80c48805db97de7af628 #LiftStationSolutions #WastewaterManagementMITSUBISHIELECTRICAUTOMATION.NOTION.SITEThe AI workspace that works for you. | NotionA tool that connects everyday work into one space. It gives you and your teams AI tools—search, writing, note-taking—inside an all-in-one, flexible workspace.0 Comments 0 Shares1

- How Conveyor System Automation Cuts Costs and Boosts Speed

The conveyor systems have improved the mechanization of moving goods beyond mere mechanical movement to smart, data-driven control. Combined with high-level machine tool stations, these systems can assist facilities in achieving a new speed, consistency, and cost-effectiveness. We will see how automation of conveys achieves this and why progressive operators are implementing such solutions.

Read More: https://mitsubishi.livepositively.com/how-conveyor-system-automation-cuts-costs-and-boosts-speed/

#conveyorsystemautomation #automatedlineofrobotsHow Conveyor System Automation Cuts Costs and Boosts Speed The conveyor systems have improved the mechanization of moving goods beyond mere mechanical movement to smart, data-driven control. Combined with high-level machine tool stations, these systems can assist facilities in achieving a new speed, consistency, and cost-effectiveness. We will see how automation of conveys achieves this and why progressive operators are implementing such solutions. Read More: https://mitsubishi.livepositively.com/how-conveyor-system-automation-cuts-costs-and-boosts-speed/ #conveyorsystemautomation #automatedlineofrobots0 Comments 0 Shares1

- Why Wastewater Lift Station Clog Solutions Are Critical for Maintenance

An important part of the reliability of sewer systems is managing the clogs in wastewater lift stations. As soon as lift stations become clogged, the failures can result in anything from overflow and expensive damage, to environmental contamination and harm to human health. Clogs typically occur from wipes, grease and debris, which causes undue stress on pumps and other infrastructure. Clog mitigation approaches typically combine mechanical screening, designs specifically for clog resistance, real time monitoring, and preventive maintenance. In addition to technology, having well trained staff and adherence to strict procedures helps to manage occurrence of clogs. By implementing proactive strategies, facilities can decrease down time, improve equipment life cycle, and protect the community from expensive failures.

Read More: https://mitsubishielectricfactoryautomation.weebly.com/blog/why-wastewater-lift-station-clog-solutions-are-critical-for-maintenance

#wastewaterliftstationsolutions #machinetoolstationsWhy Wastewater Lift Station Clog Solutions Are Critical for Maintenance An important part of the reliability of sewer systems is managing the clogs in wastewater lift stations. As soon as lift stations become clogged, the failures can result in anything from overflow and expensive damage, to environmental contamination and harm to human health. Clogs typically occur from wipes, grease and debris, which causes undue stress on pumps and other infrastructure. Clog mitigation approaches typically combine mechanical screening, designs specifically for clog resistance, real time monitoring, and preventive maintenance. In addition to technology, having well trained staff and adherence to strict procedures helps to manage occurrence of clogs. By implementing proactive strategies, facilities can decrease down time, improve equipment life cycle, and protect the community from expensive failures. Read More: https://mitsubishielectricfactoryautomation.weebly.com/blog/why-wastewater-lift-station-clog-solutions-are-critical-for-maintenance #wastewaterliftstationsolutions #machinetoolstations0 Comments 0 Shares1

- 0 Comments 0 Shares1

- 0 Comments 0 Shares1

More Stories