1. Introduction

Dubai’s expansion in infrastructure—from bright new skyscrapers to sprawling utility networks—demands high-quality piping systems. HDPE (High-Density Polyethylene) pipelines are preferred for their resistance to corrosion, flexibility, and long lifespan. Yet, the true performance of these pipes depends on the quality of their welded joints. Precision tools that enable perfect alignment, temperature control, and pressure are essential to ensure seamless results.

2. Understanding Butt Fusion Welding

Butt fusion is a welding method where two pipe ends are heated with a plate, then pressed together to form a uniform joint. As the materials cool, they fuse into a seamless connection. This technique is widely respected for creating strong, leak-proof joints crucial for both underground and above-ground installations. Unlike mechanical couplings, butt fusion avoids seals that may degrade over time or under pressure.

If you're managing an installation and searching for a butt fusion machine Dubai, Franctec Trading offers equipment that brings accuracy, repeatability, and safety to your jobsite. Their solutions are tailored for projects across Dubai, from municipal pipe laying to industrial fluid systems, ensuring both speed and structural integrity.

3. Why Infrastructure in Dubai Benefits from Butt Fusion

Dubai’s climate—hot, dusty, with rapid construction cycles—demands welding equipment that excels under pressure. Butt fusion machines withstand these conditions and maintain precision. Joints made with this technique resist soil movement, thermal shifts, and prolonged water contact. This method is vital for sectors like utilities, construction, oil and gas, and district cooling, where failures are costly.

4. Franctec Trading: A Trusted Local Provider

Franctec Trading has established its reputation as a reliable supplier of fusion and fabrication equipment in Dubai. Their expertise lies not just in selling tools, but supporting clients through selection, training, and service. They're recognized for providing machines that meet ISO and DVS standards, essential in the UAE’s rigorous regulatory landscape. Franctec’s local presence means quicker delivery, parts availability, and responsive technical support—crucial aspects for contractors working under tight schedules.

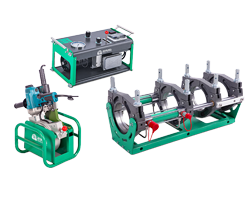

5. Key Features of Franctec’s Butt Fusion Machines

Franctec’s machines come with design features engineered for precision and durability:

-

Digital temperature control, ensuring uniform heat across pipe ends.

-

Hydraulic pressure systems that automate alignment and reduce manual errors.

-

Swappable heating plates for different pipe diameters.

-

Portable yet robust construction, ideal for moving between city and desert sites.

-

Data logging options to record parameters for quality control.

-

Built-in safety features, like pressure release and emergency stops.

These features help contractors achieve high productivity, even in high-volume environments.

6. Applications Across Dubai and the UAE

Butt fusion welding is used extensively across sectors:

-

Water Utilities: Creating strong, leak-resistant joints for drinking water networks.

-

Gas Distribution: Ensuring airtight connections vital for safety.

-

Industrial Plants: Managing chemical transport pipelines with durable welds.

-

District Cooling: Building pipeline systems that serve entire neighborhoods reliably.

-

Treatment Facilities: Connecting high-pressure HDPE lines in sewage and wastewater networks.

Each industry demands joints that can handle internal pressure and external stress, and butt fusion delivers on these needs.

7. Advantages of Choosing Franctec’s Equipment

With Franctec’s butt fusion machines, users gain several tangible benefits:

-

Operational efficiency—shorter cycle times accelerate project progress.

-

Durability and quality—seamless joints can last decades without leaks.

-

Standard compliance—phased processes ensure regulatory approval.

-

Wide support network—local training, service, and spare parts availability.

-

Scalable solutions—machines accommodate different production needs, from small batches to continuous operations.

These advantages help streamline logistics, lower downtime, and boost client satisfaction.

8. Technical Benefits for Project Delivery

Franctec’s machines also include several technical benefits:

-

User-friendly interfaces that reduce training time.

-

Precision clamping systems for optimal pipe alignment.

-

Minimal maintenance thanks to high-quality components.

-

Data output tools, like USB logging, support audit and traceability needs.

-

Adaptability to remote and harsh environments with rugged design.

These help engineering teams stay ahead of project timelines without sacrificing quality.

9. Local Expertise + Global Standards

Franctec Trading bridges local needs and global expertise. Their staff understand logistics, regulatory frameworks, and project cycles in the UAE. Meanwhile, their machines adhere to leading global standards, ensuring every weld achieves international levels of integrity.

This dual advantage helps contractors meet both local compliance and global client expectations.

10. Conclusion

For contractors working in Dubai’s fast-evolving infrastructure landscape, a precise, efficient welding process is vital. A reliable butt fusion machine ensures HDPE pipes deliver long-term, leak-free performance. Franctec Trading offers expertly designed machines, tailored training, and dedicated local support—making them the go-to choice for projects that demand both excellence and reliability.

When precision, efficiency, and durability matter, investing in a high-quality butt fusion solution from Franctec pays off in project success and peace of mind.