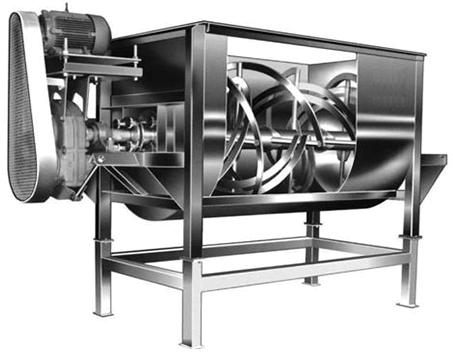

Industrial mixing equipment plays a critical role in industries ranging from food and pharmaceuticals to chemicals and construction materials. Among these machines, the ribbon blender mixer stands out as one of the most popular tools for achieving uniform and efficient blending of powders, granules, and semi-wet materials.

However, while ribbon blenders are highly effective, they are also large, powerful machines that must be handled with care. Without proper safety practices, operators risk accidents, contamination, equipment damage, and production downtime. In this article, we’ll explore the key safety practices to follow when working with ribbon blenders and how companies can maintain both worker safety and product integrity.

Why Safety Matters in Ribbon Blender Operations

A ribbon mixer uses a set of helical blades (inner and outer ribbons) mounted on a horizontal shaft. As the ribbons rotate, they move materials in opposite directions, achieving a homogeneous blend in a short time. While this design ensures efficiency, it also introduces potential hazards:

-

Mechanical hazards: The rotating shaft and ribbons can cause severe injury if the machine is accessed while running.

-

Electrical hazards: Faulty wiring, moisture, or improper grounding can result in electrical shocks.

-

Dust hazards: Powders like flour, sugar, or chemicals can cause respiratory issues and even pose explosion risks if not handled properly.

-

Contamination risks: In food or pharma production, improper cleaning can lead to cross-contamination and safety violations.

Given these risks, following safety protocols is non-negotiable.

Pre-Operation Safety Checks

Before starting a Ribbon Blender Machine, operators should complete the following checklist:

-

Inspect the Equipment – Look for signs of wear, loose bolts, or unusual noises from previous shifts.

-

Check Guards and Covers – Ensure all protective covers are in place and secured. Never run the machine without guards.

-

Verify Emergency Stops – Test all emergency stop buttons and safety interlocks to confirm they are working.

-

Clean the Blender – Remove any leftover material from previous batches to prevent contamination.

-

Lubricate Moving Parts – Follow the manufacturer’s guidelines for lubrication to avoid overheating or friction-related damage.

Safe Operation Practices

1. Training and Authorization

Only trained and authorized personnel should operate a ribbon blender. Workers must understand the control panel, emergency systems, and standard operating procedures (SOPs).

2. Personal Protective Equipment (PPE)

Operators should wear:

-

Safety goggles or face shields to protect against dust.

-

Respiratory masks when handling fine powders.

-

Gloves and protective clothing to reduce exposure to chemicals.

-

Hearing protection if the machine operates in a noisy environment.

3. Loading the Blender Safely

-

Do not overload the blender beyond its rated capacity, as this may strain the motor and cause uneven mixing.

-

Add materials gradually to avoid sudden blockages.

-

Avoid placing hands or tools inside the blender during loading; use feeding hoppers or conveyors instead.

4. During Operation

-

Never bypass safety interlocks or open inspection ports while the machine is running.

-

Monitor vibration, noise levels, and motor temperature. Unusual signs may indicate imbalance or mechanical failure.

-

Keep the working area clean to prevent slips or contamination hazards.

5. Unloading and Cleaning

-

Ensure the machine is fully stopped and locked out before discharging material.

-

Use appropriate tools, not hands, to clear any material stuck near the discharge valve.

-

Clean the blender thoroughly after each batch to maintain hygiene standards, especially in food and pharmaceutical industries.

Lockout/Tagout (LOTO) Procedures

One of the most important safety practices in ribbon blender operations is following lockout/tagout (LOTO) protocols. This ensures the machine cannot be accidentally powered on during maintenance or cleaning. Steps include:

-

Disconnect the blender from its power source.

-

Lock the power switch with a padlock and attach a tag indicating maintenance work is in progress.

-

Verify by attempting a start—confirm the machine does not power on.

-

Only after completing maintenance and inspections should the lock and tag be removed.

Preventing Dust Hazards

Powder handling comes with dust-related risks, including respiratory issues and fire hazards. Safety measures include:

-

Installing dust extraction systems or bag filters.

-

Using sealed hoppers for feeding raw materials.

-

Ensuring the work area has proper ventilation.

-

Training workers on the dangers of combustible dust and emergency procedures.

Maintenance Safety Practices

Routine maintenance is essential for both safety and performance:

-

Regular Inspections: Check shafts, bearings, and seals for wear. Replace damaged parts immediately.

-

Blade Alignment: Misaligned ribbons can cause uneven mixing and strain the motor.

-

Lubrication Schedule: Over- or under-lubrication can lead to overheating or failure.

-

Calibration: Ensure discharge valves and sensors are calibrated for precise control.

Maintenance teams must always follow LOTO procedures and use proper PPE.

Industry-Specific Safety Considerations

-

Food Industry: Focus on hygiene and allergen control. Stainless steel construction is preferred for easier cleaning.

-

Pharmaceutical Industry: Follow GMP (Good Manufacturing Practice) guidelines, ensuring no cross-contamination.

-

Chemical Industry: Ensure the blender material is compatible with corrosive or abrasive powders. Explosion-proof motors may be required.

Building a Safety Culture

Beyond equipment-specific practices, creating a culture of safety is key:

-

Conduct regular safety training sessions.

-

Encourage workers to report unsafe conditions without fear.

-

Display clear SOPs and safety signage near the machine.

-

Perform periodic audits to ensure compliance with regulations such as OSHA or GMP.

Conclusion

The ribbon blender mixer is a powerful and versatile machine, but its efficiency comes with inherent risks if not handled correctly. By following proper pre-operation checks, safe handling practices, dust control measures, and strict maintenance routines, operators can significantly reduce hazards.

Investing in safety not only protects workers but also enhances productivity, reduces downtime, and ensures compliance with industry standards. Whether you’re using a large industrial ribbon mixer in a chemical plant or a specialized Ribbon Blender Machine in food or pharmaceutical production, prioritizing safety practices is the foundation of long-term success.