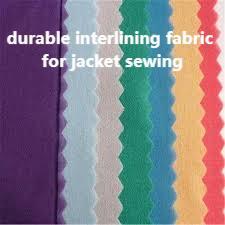

In modern tailoring, durable interlining fabric for jacket sewing offers the essential backbone that enhances shape and longevity by reinforcing critical areas without visible bulk.

Structural Advantages of Quality Interlining

Interlining acts as the invisible scaffold within a jacket, lending stability to collars, lapels, and front panels. Through even stress distribution along seams and edges, it prevents fabric distortion as the wearer moves. By selecting the right interlining weight—light for unlined blazers, medium for classic sport coats, and heavy for winter overcoats—designers can achieve a perfect balance between support and drape. A well-chosen layer not only maintains the intended silhouette but also elevates the perceived value of every garment.

Material Selection and Weight Considerations

When selecting durable interlining fabric for jacket sewing, understanding fiber composition and thickness is crucial. Polyester blends offer strength and resilience, while cotton-based interlinings provide breathability for warmer-weather garments. Specialty heat-resistant yarns enable high-temperature pressing without discoloration. Medium-weight options often serve as a versatile compromise, supporting structure without adding excessive stiffness. By matching interlining weight to outer fabric characteristics—such as pairing midweight fusible interlinings with wool blends—tailors ensure optimal hand feel and movement.

Brand Spotlight: Pellon’s Fusion Collection

Pellon’s Fusion Collection has become a go-to for professionals seeking reliable fusible interlinings. Known for its consistent bonding power and minimal thickness, this line accommodates both machine and hand application methods. Its breathable construction allows moisture to escape, reducing the risk of adhesive seepage onto delicate exteriors. Many ateliers choose Pellon when crafting denim jackets or structured tuxedo styles, appreciating quick bond times and uniform adhesion that withstand numerous cleaning cycles without delamination.

Application Techniques for Seamless Integration

Achieving a flawless finish requires more than just choosing the right product; precise application is equally vital. Fusible interlinings demand calibrated heat and pressure: too hot may scorch delicate fabrics, too cool results in weak bonds. Sew-in variants call for consistent stitch tension and appropriate stitch length to prevent puckering. Advanced tailors often perform trial presses on scrap material to fine-tune temperature and timing. Whether using a steam iron or professional heat press, meticulous technique transforms interlining application from a basic step into an art form.

Care Protocols for Lasting Performance

The longevity of a jacket depends significantly on proper maintenance. To preserve interlining integrity, follow manufacturer guidelines for dry-cleaning solvents and pressing temperatures. High-heat home ironing can weaken adhesive bonds, so recommend professional steaming whenever possible. Delicate garments may benefit from protective cloths during pressing to prevent shine or scorch marks. Educating customers on correct handling and storage—including hanging on broad-shouldered hangers—ensures the internal support remains undisturbed, keeping jackets looking pristine season after season.

By combining thoughtful material choice, expert application, and conscientious care, tailors create jackets that not only look impeccable but also endure the rigors of daily wear. The unseen strength of modern interlinings transforms every garment into a masterpiece of both form and function.

interlining-factory.com