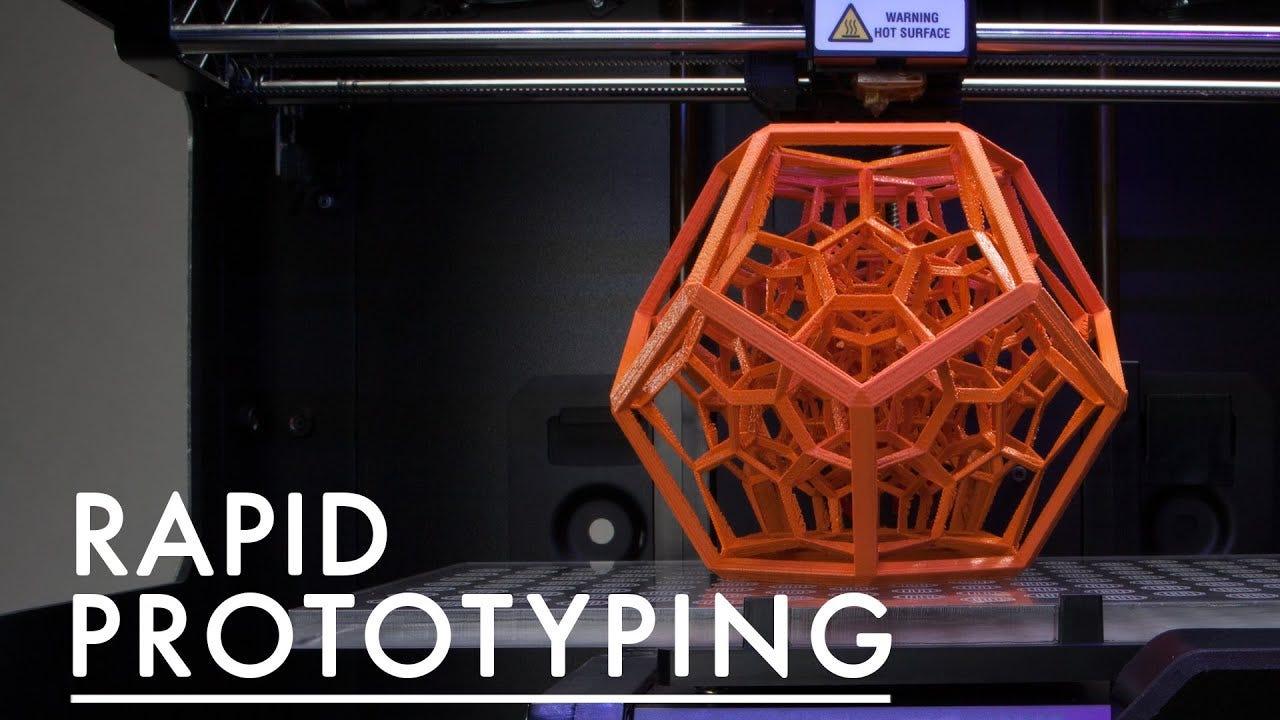

The tools of industrial creation are no longer locked behind the factory gates. A new paradigm, powered by online platforms and advanced fabrication technologies, is granting startups and Fortune 500 companies alike instant access to a global manufacturing network. Rapid prototyping services have become the great equalizer, turning CAD files into physical parts with a click, thereby democratizing hardware development and fueling a new wave of technological creativity.

This accessibility is driving remarkable economic expansion. According to Straits Research, the global rapid prototyping service sector was valued at USD 2.47 billion in 2024 and is expected to grow from USD 2.87 billion in 2025 to reach USD 9.68 billion by 2033, growing at a CAGR of 16.4% during the forecast period (2025-2033). This growth trajectory underscores a fundamental shift in how physical products are designed, tested, and brought to life.

Analysis of a Fragmented yet Collaborative Arena

The competitive field isn't a zero-sum game; it's an ecosystem where platform aggregators and specialized experts coexist.

-

The Platform Powerhouses: Xometry (USA) and Protolabs (USA) are engaged in a fierce battle for market dominance through scale and technology. Xometry’s asset-light marketplace model allows for an immense capacity and variety of processes, including CNC machining, vacuum casting, and sheet metal fabrication alongside 3D printing. Their growth analysis points to international expansion and deeper software integration as key drivers. Protolabs, with its owned-and-operated facilities, competes on guaranteed speed, consistency, and proprietary automation software, recently enhancing its injection molding service for faster turnaround on complex molds.

-

The Specialized Leaders: Success is also found in specialization. Shapeways (USA), after a transition to a purely software-focused model, now empowers other businesses to launch their own customized manufacturing services. In Germany, Siemens AG has integrated prototyping services deeply into its NX software and Digital Enterprise suite, offering a seamless path from design to physical verification within a single digital thread. This caters to complex industries like automotive and aerospace.

-

Regional Champions and Niche Experts: Local players thrive on proximity and expertise. Companies like 3ERP (China) compete on cost-effectiveness and high-volume prototyping for the Asian electronics sector. In the medical field, services like 3D Systems' QuickParts (USA) specialize in biocompatible and sterilizable materials for surgical guides and medical device prototypes, navigating strict regulatory environments that generalists cannot.

Global Trends Defining the Next Decade

The service is evolving in three critical directions:

-

AI-Driven Design and Fabrication: Artificial intelligence is moving into the core of the service offering. AI algorithms are now used to automatically orient parts for optimal printing, generate support structures that minimize material use, and even predict potential print failures before an order is placed. This intelligence increases first-time success rates and reduces costs.

-

The Rise of Distributed Manufacturing: The model of a centralized service bureau is being complemented by distributed networks. Platforms are leveraging smaller, local fabrication hubs to fulfill orders, drastically reducing shipping times and costs. This trend towards localized production enhances supply chain resilience and agility.

-

Advanced Materials Driving New Applications: The development of new materials is unlocking new applications. Services now offer prototypes in engineering-grade materials like peek filament, copper alloys, and ceramic composites. This allows for functional testing under real-world stresses, thermal conditions, and chemical exposures, providing invaluable data long before mass production begins.

Recent News and Competitive Developments

The industry is rife with strategic moves. A key recent update is Stratasys Ltd. (Israel/USA) announcing a new program to make its high-end FDM and PolyJet technologies more accessible through its partner service bureau network. In Japan, Ricoh Industries has launched a new industrial-grade SLS printing service focused on durable nylon parts for the automotive and consumer electronics industries. Furthermore, the acquisition of smaller, innovative bureaus by larger entities continues, as seen with Proto Labs' ongoing strategy to acquire complementary capabilities in specific regions or technologies.

In summary, the rapid prototyping service industry is a dynamic and critical enabler of modern engineering, characterized by the clash of platform-based and specialist models. Driven by AI, new materials, and a shift towards localized production, it is fundamentally changing how ideas are transformed into tangible realities, accelerating innovation across the globe.