The factors driving Manufacturing Analytics Market Growth include the increasing demand for predictive maintenance, production optimization, and cost reduction in manufacturing operations. Analytics solutions leverage big data, AI, and IoT to transform traditional production environments into smart, data-driven systems.

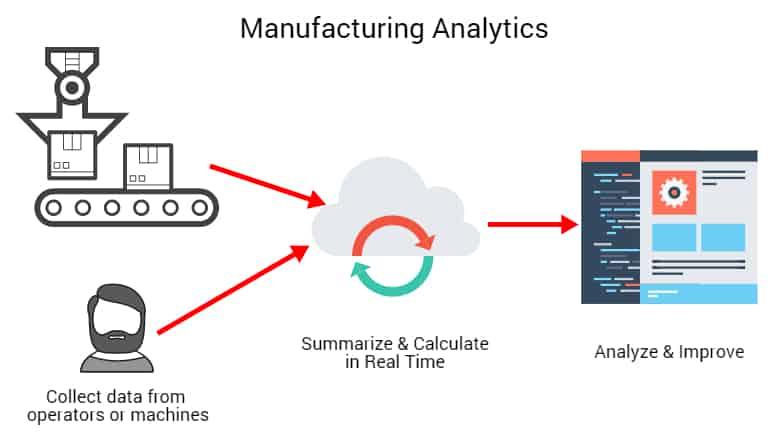

Real-time monitoring of machinery and production processes enables manufacturers to detect inefficiencies, prevent breakdowns, and optimize workflows. Analytics also supports supply chain optimization by forecasting demand, minimizing inventory costs, and improving resource allocation. These benefits have led to accelerated adoption across industries.

Cloud-based analytics solutions are a major growth driver, offering scalability, cost-effectiveness, and remote accessibility. Manufacturers can deploy analytics tools without significant upfront investment, enabling smaller firms to access advanced technologies and compete with larger players. Integration of digital twins and AI-driven analytics further accelerates market expansion.

Geographically, North America and Europe dominate the market, but Asia-Pacific shows substantial growth potential due to industrialization, government initiatives, and rising adoption of smart manufacturing solutions. Strategic collaborations, mergers, and acquisitions by key market players further enhance growth prospects.

Manufacturing analytics market growth is fueled by technological advancements, operational efficiency needs, and predictive insights. As more companies embrace analytics-driven operations, the market is poised for sustained expansion, transforming manufacturing into a highly efficient, data-driven ecosystem.