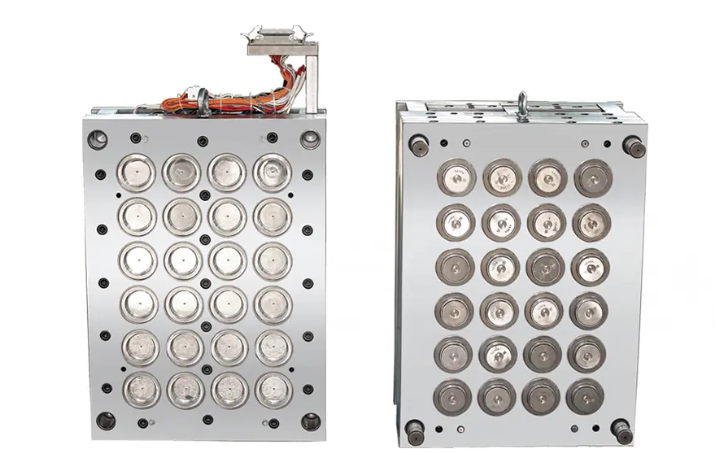

A Plastic Cap Mold is a capital asset whose longevity determines the overall profitability of a bottling operation, yet many plants overlook preventive care until costly unplanned downtime strikes. Scheduled maintenance of the Plastic Cap Mold begins with daily inspections of cavity vents and ejector pins, ensuring that no plastic residue blocks airflow or mechanical motion. Technicians use lint-free cloths soaked in food-grade solvent to wipe the Plastic Cap Mold surface, removing oils and dust that could transfer onto closures. Every forty operating hours, the Plastic Cap Mold is removed from the press and heated in an oven to 120 °C to evaporate moisture trapped in micro-cracks, preventing corrosion of delicate gate areas. High-wear components such as neck-ring inserts and stripper rings are measured with micrometers; if diameters deviate by more than twenty microns from nominal, replacements are installed to keep the Plastic Cap Mold producing caps within specification. Grease formulated with PTFE is injected into leader pins and bushings every week, creating a lubricating film that withstands millions of cycles without washing away. Cooling circuits are flushed monthly with a citric-acid solution to dissolve mineral deposits that reduce heat transfer efficiency, indirectly lengthening cycle time and stressing the Plastic Cap Mold steel. Advanced plants deploy ultrasound probes to detect fatigue cracks inside the Plastic Cap Mold before they propagate to catastrophic failure. A cloud-based CMMS stores torque values, temperature logs, and photographs for each Plastic Cap Mold, enabling predictive algorithms to forecast optimal rebuild dates. During planned shutdowns, the Plastic Cap Mold is disassembled, and cavity surfaces are re-polished to restore gloss and remove micro-scratches. Hot-runner heaters and thermocouples are calibrated so that every cavity of the Plastic Cap Mold sees identical thermal conditions, ensuring uniform shrinkage and thread quality. Finally, desiccant packs are sealed inside the Plastic Cap Mold before storage, keeping humidity below thirty percent and protecting precision ground surfaces. By treating the Plastic Cap Mold as a living system that breathes, heats, and cools, forward-thinking manufacturers routinely surpass ten million cycles without major rework, turning maintenance from a cost center into a competitive advantage.

-

NEUIGKEITEN

- EXPLORE

-

Seiten

-

Gruppen

-

Veranstaltungen

- Blogs

- Jobs

- Foren

Search

Nach Verein filtern

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

How Access to Cancer Care Is Influencing the MEA Taxane Market

Key Drivers Impacting Executive Summary Middle East and Africa Taxane Market Size and...

Navigating the Fastest-Growing City in America

Austin has changed dramatically in the last decade, and the transportation landscape has expanded...

POE 2-The Power Combo: Evasion Backed by Recovery

Hey everyone, today we're going to talk about defensive layers and how to stop dying in Path of...

Global Linear Particle Accelerators Market Insights: Growth, Share, Value, Size, and Trends

"Executive Summary Linear Particle Accelerators Market :

Global linear particle...

Stage Production Tokyo Premiere – Global Tour Expands

Prepare for a magical journey across the globe

as the acclaimed stage production expands its...