In recent years, 3D printed snap fit joints have revolutionized product design and assembly. These joints allow for easy, tool-free assembly of components, which is particularly valuable in rapid prototyping and small-scale manufacturing. However, the precision and performance of snap fit joints are highly dependent on the design process. To achieve high accuracy and durability, engineers rely on advanced design software tools that simulate mechanical behavior, material properties, and tolerance constraints before printing. By leveraging these tools, designers can predict potential failures, optimize geometries, and significantly reduce production costs.

With the increasing adoption of additive manufacturing in industries such as aerospace, automotive, and consumer electronics, the demand for precise 3D printed snap fit joints has surged. Unlike traditional manufacturing, 3D printing allows for complex geometries that were previously impossible to achieve. This capability, however, comes with the challenge of ensuring that snap fit joints perform as intended under mechanical stress and repeated use. Modern design software provides engineers with the necessary platform to create, test, and refine these joints virtually, saving both time and resources.

CAD Software for Designing Snap Fit Joints

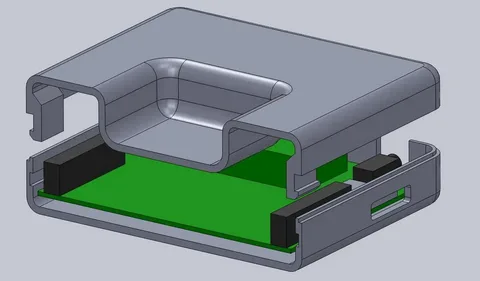

Computer-Aided Design (CAD) software is the cornerstone for developing high-precision 3D printed snap fit joints. Tools like SolidWorks, Autodesk Fusion 360, and PTC Creo offer intuitive interfaces for creating complex 3D geometries with exact dimensions. These platforms allow designers to manipulate parameters such as taper angles, cantilever lengths, and living hinges, which are critical for the performance of snap fit joints. CAD software also enables version control and collaboration, allowing multiple engineers to work on a single design while maintaining accuracy.

Moreover, CAD tools provide parametric modeling capabilities, which are essential for customizing snap fit joints to different materials and print technologies. By adjusting parameters like wall thickness and notch dimensions, engineers can ensure that the joints snap together without excessive force or risk of breakage. Many CAD platforms also offer integrated simulation features that help predict stress distribution and deformation in the joint, ensuring that the design meets functional requirements before moving to the 3D printing stage.

Simulation Tools for Stress and Strain Analysis

Simulation software plays a vital role in validating 3D printed snap fit joints. Finite Element Analysis (FEA) tools, such as ANSYS, Abaqus, and COMSOL Multiphysics, allow engineers to simulate real-world forces on snap fit joints, including bending, shear, and torsional stresses. These simulations help predict how the joint will behave under repeated assembly and disassembly, preventing potential failures and material fatigue. Accurate stress analysis ensures that the snap fit maintains its structural integrity over time, which is crucial for high-performance applications.

In addition to mechanical analysis, simulation tools can model thermal and environmental effects on 3D printed snap fit joints. For example, certain plastics may soften under heat, affecting the joint’s holding strength. By running simulations that account for temperature, humidity, and UV exposure, engineers can select suitable materials and adjust the joint design accordingly. This proactive approach minimizes trial-and-error iterations in physical prototyping, saving significant time and costs while enhancing the overall reliability of the final product.

Generative Design and Topology Optimization Tools

Generative design and topology optimization software are emerging as powerful tools for creating advanced 3D printed snap fit joints. Programs like Autodesk Generative Design, nTopology, and SolidThinking Inspire use algorithms to generate multiple design alternatives based on user-defined constraints such as load capacity, material usage, and space limitations. This process allows engineers to discover innovative joint geometries that traditional design methods may overlook, resulting in lightweight, strong, and efficient designs.

Topology optimization not only improves mechanical performance but also enhances manufacturability. By identifying unnecessary material within the snap fit joint, engineers can reduce printing time, material waste, and post-processing requirements. Additionally, these tools can integrate seamlessly with CAD and FEA platforms, allowing for iterative optimization cycles where performance predictions are continually refined. This synergy ensures that the 3D printed snap fit joints are both functionally superior and cost-effective.

Software for Tolerance and Fit Analysis

Tolerance and fit are critical considerations when designing 3D printed snap fit joints. Software tools like Geomagic Control, PolyWorks, and Verisurf provide comprehensive metrology solutions that ensure the printed components meet precise dimensional specifications. By simulating the effects of printer resolution, material shrinkage, and assembly tolerances, designers can adjust the joint geometry to achieve optimal fit and function. Accurate tolerance analysis minimizes issues like joint looseness, excessive force during assembly, or part failure.

These tools also help in predicting how different 3D printing technologies, such as SLA, SLS, or FDM, impact joint precision. Each technology has unique characteristics, including layer adhesion, surface roughness, and dimensional accuracy, which can influence the performance of snap fit joints. By incorporating tolerance analysis into the design workflow, engineers can make informed decisions regarding printer selection, orientation, and post-processing methods, ensuring reliable and repeatable assembly.

Integrated Platforms for End-to-End Design and Validation

The ultimate efficiency in designing 3D printed snap fit joints comes from integrated software platforms that combine CAD, simulation, optimization, and analysis in a single workflow. Platforms like Siemens NX, Autodesk Fusion 360, and PTC Creo Parametric provide comprehensive environments where engineers can design, test, and refine snap fit joints without switching between multiple software. This integration reduces errors, improves collaboration, and accelerates the time-to-market for new products.

Integrated platforms also offer cloud-based collaboration, version tracking, and automated reporting, which are particularly beneficial for distributed design teams. Engineers can simulate multiple scenarios, iterate designs, and validate performance data, ensuring that the snap fit joints meet functional requirements before committing to physical production. The combination of design, analysis, and optimization in a unified environment makes it possible to create high-precision 3D printed snap fit joints that perform reliably in demanding applications.

Conclusion

The development of 3D printed snap fit joints has transformed modern product assembly, offering flexibility, strength, and efficiency. Achieving high precision and reliable performance, however, depends on the effective use of advanced design software tools. From CAD platforms to simulation, generative design, tolerance analysis, and integrated design environments, these tools empower engineers to predict performance, optimize geometry, and ensure repeatability.