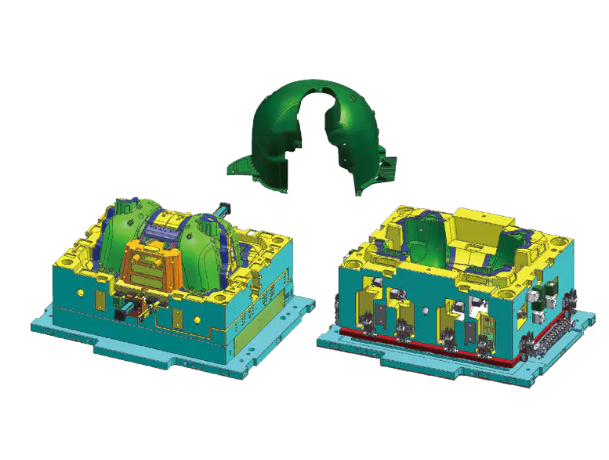

Environmental stewardship is engineered into every facet of the Auto SGM Plastic Front Mudguard Injection Mold, making it the preferred choice for OEMs pursuing aggressive carbon-reduction targets without compromising quality. The Auto SGM Plastic Front Mudguard Injection Mold starts with responsibly sourced tool steel certified by recycled-content schemes, reducing embodied carbon by 9 % compared to conventional molds. Inside the Auto SGM Plastic Front Mudguard Injection Mold, a valve-gated hot-runner system eliminates cold-runner waste entirely, saving roughly 250 kg of resin per 10 k parts and diverting material from landfill or energy-intensive regrind. Optimized conformal cooling channels within the Auto SGM Plastic Front Mudguard Injection Mold lower cycle energy by 11 %, cutting kWh per part and shrinking the carbon footprint of each front mudguard. The Auto SGM Plastic Front Mudguard Injection Mold is compatible with bio-based polypropylene grades, validated to process 30 % plant-derived resin while still meeting impact specifications. Longevity coatings on the Auto SGM Plastic Front Mudguard Injection Mold extend preventive-maintenance intervals, reducing solvent-based cleaning chemicals that must be treated as hazardous waste. At end-of-life, 92 % of the Auto SGM Plastic Front Mudguard Injection Mold mass can be recycled through established metal-recovery streams, avoiding landfill disposal. Packaging for the Auto SGM Plastic Front Mudguard Injection Mold utilizes reusable steel crates that eliminate single-use timber and foam, saving 1.2 m³ of waste per shipment. Life-cycle analysis shows that selecting the Auto SGM Plastic Front Mudguard Injection Mold cuts Scope 3 emissions by 0.6 kg CO₂-e per mudguard when calculated across a 200 k part program. Continuous improvement programs tied to the Auto SGM Plastic Front Mudguard Injection Mold track energy and material KPIs, ensuring environmental gains compound over successive model years.

Zoeken

Categorieën

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

US Automotive Rear Seat Infotainment Size Market Experiences Growth Amid Economic Recovery Efforts

"Harnessing Opportunities for US Automotive Rear Seat Infotainment Market

As per MRFR analysis,...

Why Do You Need a Smart Home Control Panel Instead of a Traditional Hub?

Traditional smart home control panel hubs have been the backbone of home automation for years,...

How do intra aortic balloon pumps work in heart treatment?

What’s Fueling Executive Summary Intra Aortic Balloon Pumps Market Size and Share Growth...

Optical Coating Market Fast growth at a highest CAGR to forecast period by 2030

A report by Allied Market Research projects that the global optical coating market, is...

Apexcreative Marketing – Expert SEO Company Delaware for Local Businesses

In today’s competitive online marketplace, visibility is critical to business success....