The 3D printing plastics market is charting new territory, with applications spanning from surgical implants to aerospace components. As industries seek faster, more efficient production methods, 3D printing plastics offer a compelling blend of strength, adaptability, and cost-effectiveness.

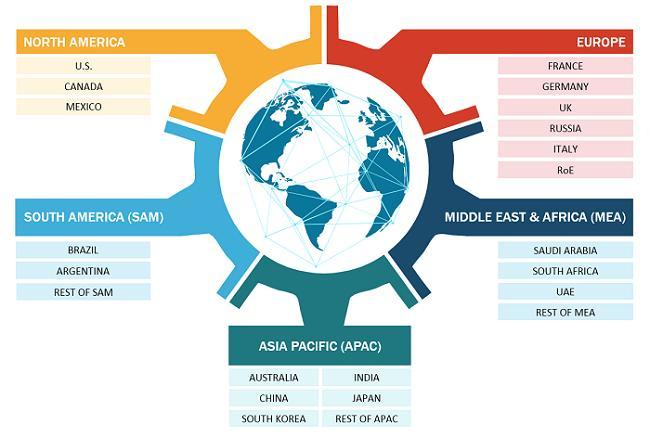

The market’s growth is fueled by innovations in material science, with polyamide and polylactic acid gaining prominence for their unique properties. Regional dynamics also play a key role, with Asia Pacific emerging as a hub for additive manufacturing.

Forecast Highlights by 2031:

-

Strong demand for ABS and nylon in automotive and defense sectors.

-

Filament and liquid/ink forms dominate medical and electronics applications.

-

North America and Europe show steady growth, with Asia Pacific leading innovation.

-

Trends include hybrid printing systems, recyclable materials, and smart inspection overlays.

-

Market share expected to diversify across emerging end-use industries.

Updated Market News: Clariant International Ltd. has introduced a new line of flame-retardant filaments for aerospace use, while ExOne GmbH is expanding its powder-based solutions for high-temperature applications.