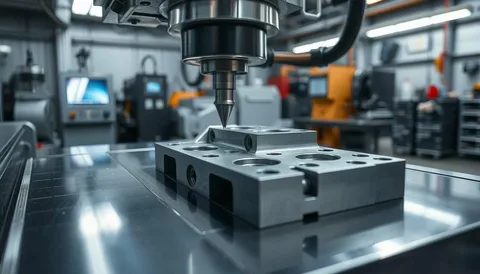

In the modern manufacturing landscape, the ability to rapidly and accurately produce prototypes is critical for businesses looking to innovate and stay ahead of the competition. CNC machining services play a pivotal role in turning conceptual designs into tangible prototypes, offering unmatched precision and efficiency. These services leverage advanced computer-controlled machinery to produce components that meet exact specifications, reducing errors and saving valuable time during the product development process. By utilizing CNC machining, engineers and designers can iterate quickly, validate designs, and bring products to market faster.

Precision prototyping is more than just producing a sample part; it is about ensuring that every component meets stringent dimensional tolerances and material requirements. CNC machining services provide the flexibility to work with a wide range of materials, including metals, plastics, and composites, enabling manufacturers to simulate real-world conditions for their prototypes. With these services, businesses can explore complex geometries and intricate designs that would be challenging to achieve through traditional methods, ensuring a higher likelihood of success during full-scale production.

The Importance of Precision in Prototyping

Precision is the cornerstone of effective prototyping. A small deviation in dimensions can lead to functional issues, assembly problems, or performance inefficiencies in the final product. CNC machining services offer high accuracy by relying on computer-controlled operations that eliminate human error. Every cut, drill, and contour is executed with a level of precision that ensures prototypes are as close to the final product as possible, which is vital for testing, validation, and client presentations.

Moreover, precision prototyping allows for cost-effective development cycles. Traditional manufacturing methods often require multiple iterations, which can be both time-consuming and expensive. CNC machining services reduce this need by producing prototypes that meet exact design specifications from the outset. This level of accuracy not only speeds up the development process but also helps identify potential design flaws early, saving money and resources in the long run.

Versatility of CNC Machining Services

One of the greatest advantages of CNC machining services is their versatility. These services are capable of producing a wide variety of shapes and designs, from simple components to highly intricate parts that would be difficult or impossible to fabricate manually. CNC machines can work with multiple materials, including aluminum, stainless steel, titanium, and high-performance plastics, providing designers with the freedom to experiment with different materials and configurations for their prototypes.

Additionally, CNC machining supports both low-volume and high-volume production, making it ideal for prototyping as well as small-batch manufacturing. Businesses can quickly switch from producing a single prototype to a series of test components without needing significant retooling. This adaptability ensures that CNC machining services remain a reliable solution for companies looking to innovate rapidly and respond to market demands efficiently.

Reducing Time-to-Market with CNC Prototyping

In today’s competitive market, speed is critical. CNC machining services significantly reduce time-to-market by streamlining the prototyping process. Unlike traditional manufacturing methods, which may require handcrafting or extensive tooling setup, CNC machines operate directly from digital CAD files. This eliminates manual intervention and accelerates the production of high-fidelity prototypes, allowing businesses to test and refine their designs faster.

Rapid prototyping using CNC machining also facilitates iterative design. Engineers can make adjustments to CAD models and produce updated prototypes in a matter of hours or days rather than weeks. This iterative approach enhances product development efficiency and ensures that the final design is optimized for performance, manufacturability, and cost-effectiveness before committing to mass production.

Quality Assurance and Consistency

Consistency is critical when developing prototypes that will eventually transition into full-scale production. CNC machining services offer unparalleled repeatability, ensuring that every prototype component adheres to the same exacting standards. This consistency helps maintain product integrity, allows for more reliable testing, and builds confidence among stakeholders, clients, and engineers that the final product will perform as expected.

Moreover, CNC machines are equipped with advanced monitoring and control systems that detect deviations in real-time, preventing errors and maintaining high-quality output. This level of quality assurance reduces the likelihood of prototype failure and provides precise data that can inform further design improvements. By using CNC machining services, businesses can achieve both precision and reliability, which are essential for successful prototyping.

Cost Efficiency and Strategic Advantages

While CNC machining may initially appear as a higher-cost option compared to manual methods, it offers significant cost efficiency over the product development lifecycle. By producing accurate prototypes the first time, businesses can reduce material waste, minimize the need for rework, and shorten development cycles. This efficiency translates into lower overall project costs and a faster return on investment.

Furthermore, CNC machining services provide strategic advantages by allowing companies to stay ahead in innovation. Access to precise, high-quality prototypes enables better product validation, early identification of design flaws, and quicker decision-making. Companies can test market readiness, gather user feedback, and iterate designs without the delays associated with traditional prototyping methods, giving them a competitive edge in rapidly changing industries.

CNC machining services have transformed the prototyping process, providing the precision, versatility, and efficiency necessary for modern product development. By leveraging these services, businesses can accelerate innovation, reduce costs, and ensure the quality and performance of their products. From complex geometries to stringent tolerances, CNC machining remains an essential tool for designers and engineers seeking to bring their ideas to life with accuracy and reliability.