In today’s manufacturing landscape, precision and accuracy are no longer optional—they are essential. Companies across industries increasingly demand parts that are not only custom-designed but also manufactured with meticulous attention to detail. Precision machining services have emerged as the solution for producing complex and custom metal components that meet exacting standards. These services employ advanced technologies and skilled professionals to deliver components that fulfill the most stringent specifications.

From aerospace and automotive to medical and electronics industries, the need for parts with tight tolerances has skyrocketed. Custom metal parts often involve intricate designs and challenging geometries that cannot be achieved through traditional manufacturing methods. Precision machining services combine computer-aided design (CAD), computer numerical control (CNC) machinery, and highly skilled machinists to produce components that are both accurate and reliable. By leveraging these services, manufacturers can ensure the quality, consistency, and performance of their products.

Advanced Techniques in Precision Machining Services

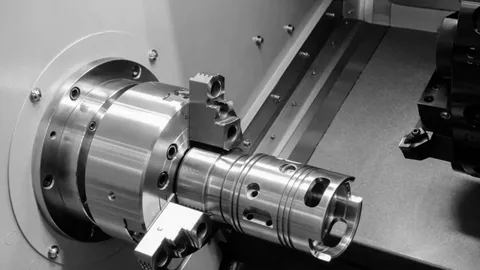

The heart of modern precision machining services lies in the use of advanced manufacturing techniques. CNC machining, turning, milling, and grinding are just a few of the processes that allow manufacturers to create complex geometries with unparalleled accuracy. CNC technology, in particular, enables the automation of production processes, ensuring consistent quality and repeatability for every custom metal part. With computer-aided programming, every cut and operation is precisely calculated to meet the specifications outlined by the client.

Beyond standard processes, many precision machining services incorporate advanced techniques such as multi-axis machining and additive manufacturing hybrid solutions. Multi-axis machining enables the creation of parts with intricate curves and angles that would be impossible to produce on conventional equipment. This capability is particularly valuable for industries such as aerospace and medical devices, where components must adhere to strict design tolerances. By adopting these advanced techniques, manufacturers can provide solutions that are both innovative and highly precise.

Customization Capabilities for Unique Metal Parts

One of the primary advantages of precision machining services is their ability to produce highly customized metal parts. Whether a project demands a single prototype or a full-scale production run, these services offer unparalleled flexibility. Machinists can work from CAD files, sketches, or even conceptual ideas to create parts that perfectly align with the client’s specifications. This customization extends beyond shape and size to include material selection, surface finishes, and functional features such as threading or engraving.

Custom metal parts are essential in industries where standard components cannot meet specific performance requirements. For instance, in the medical sector, custom surgical tools and implants must match the unique anatomy of patients. Similarly, in the aerospace industry, custom components must withstand extreme conditions while maintaining precise tolerances. By utilizing precision machining services, manufacturers can bridge the gap between concept and reality, delivering parts that are tailored to exacting requirements.

Ensuring High Quality and Tolerance Accuracy

High-quality output and strict adherence to tolerances are non-negotiable in modern manufacturing. Precision machining services utilize rigorous quality control protocols to ensure every component meets or exceeds industry standards. Techniques such as coordinate measuring machines (CMMs), laser scanning, and optical inspection help verify dimensional accuracy and surface integrity. These measures guarantee that even the most complex metal parts perform reliably in their intended applications.

Tolerance accuracy is particularly critical for parts that must fit seamlessly within larger assemblies. Any deviation, even within small margins, can compromise the functionality and safety of the final product. Precision machining services address this challenge by implementing strict process controls and continuous monitoring throughout the production cycle. By maintaining exacting standards, these services provide clients with confidence that each custom part will meet the demanding specifications required for high-performance applications.

Cost Efficiency and Production Speed

While custom and complex metal parts might suggest high costs and long production timelines, precision machining services often improve both efficiency and affordability. Advanced machinery and automated processes reduce waste, lower labor costs, and shorten production cycles. CNC programming allows for rapid adjustments and retooling, minimizing downtime and ensuring fast turnaround for both prototypes and large production runs.

Moreover, precision machining reduces the likelihood of errors and rework, which can significantly inflate costs in traditional manufacturing. By relying on automated and highly controlled processes, manufacturers achieve consistent results with minimal material waste. For businesses, this translates to reduced production costs, faster time-to-market, and the ability to scale operations without sacrificing quality. Precision machining services therefore offer a compelling combination of precision, speed, and cost-effectiveness that benefits both manufacturers and end-users.

Future Trends in Precision Machining Services

The future of precision machining services is closely tied to technological advancements and industry innovations. Automation, artificial intelligence, and machine learning are increasingly integrated into machining processes, enabling smarter production and predictive maintenance. These technologies allow machinists to anticipate issues before they arise, optimize cutting strategies, and improve overall efficiency while maintaining high levels of precision.

Additionally, the demand for lightweight, high-strength, and multifunctional materials is driving innovation in custom metal part manufacturing. Additive manufacturing and hybrid machining techniques are being combined to create parts that were previously impossible to produce. This trend indicates a future where precision machining services will not only meet complex design requirements but also push the boundaries of material performance and functional innovation, positioning manufacturers at the forefront of industrial progress.

Conclusion

Precision machining services have revolutionized the production of complex and custom metal parts, enabling industries to meet stringent design, performance, and quality requirements. Through advanced techniques, customization capabilities, and stringent quality control, these services deliver components that are accurate, reliable, and tailored to specific applications. They offer cost-efficient solutions without compromising on speed or precision, making them essential for modern manufacturing.

As technology continues to evolve, precision machining services will play an even more critical role in the development of innovative products and high-performance components. From aerospace and automotive to medical devices and electronics, businesses that leverage these services can achieve superior outcomes, streamline production, and maintain a competitive edge in an increasingly demanding market.