The manufacturing industry is one of the main pillars of any modern economy. It helps produce everything we use daily — from cars and airplanes to kitchen tools and medical devices. But behind every strong manufacturing company lies a quiet but powerful support system — the machine shop.

A machine shop is where precision, creativity, and engineering come together to shape raw materials into finished components. Without the help of machine shops, factories and industries would not be able to produce the perfectly shaped and accurate parts required for machines, vehicles, or structures.

Let’s explore, in simple and easy words, how a machine shop supports the manufacturing industry, the various services it offers, and why it plays such a vital role in modern production.

Note: Expert machine shop in Dubai offering precision machining, custom metal fabrication, and high-quality component manufacturing for industrial and engineering projects.

Understanding What a Machine Shop Is

Before we dive into how it supports the manufacturing world, let’s first understand what a machine shop actually means.

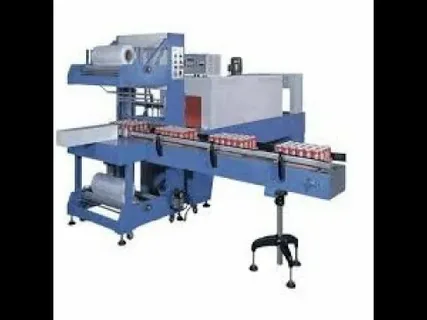

A machine shop is a specialized workshop where machines like lathes, milling machines, drilling tools, and grinders are used to shape, cut, and finish metal or plastic parts. These shops are filled with both manual and computer-controlled machines that can perform very precise operations.

Machine shops are used to create tools, components, and custom parts that fit perfectly into larger machines or products. In simple words, a machine shop turns blueprints and ideas into real, physical items.

Whether it’s a small screw, a car engine part, or an aircraft frame, every mechanical product begins with a machining process inside a machine shop.

The Role of Machine Shops in Manufacturing

Machine shops are the backbone of the entire manufacturing process. They ensure that every part used in a product is shaped accurately and functions correctly.

Here are the key ways in which they support the manufacturing industry:

Producing High-Precision Components

One of the main jobs of a machine shop is to produce high-precision parts that fit exactly where they are needed. In industries like aerospace, automotive, and electronics, even a small error in size can cause major problems.

Machine shops use advanced tools and technologies such as CNC (Computer Numerical Control) machines to create components with extreme accuracy. These machines can cut and shape materials with precision up to thousandths of a millimeter.

This level of detail ensures that every product coming out of the factory is reliable, safe, and long-lasting.

Repairing and Maintaining Equipment

Manufacturing companies depend on machines that run continuously to meet production demands. Over time, these machines wear out or need maintenance.

A machine shop helps by repairing or rebuilding worn-out machine parts instead of replacing entire systems. This reduces downtime and saves the company both time and money.

For example, if a factory machine has a damaged gear, the machine shop can create a new one using the exact measurements of the original part.

Supporting Custom and Prototype Development

Every new product begins as an idea or a prototype. Machine shops play a big role in this stage by producing custom and prototype parts that allow engineers to test their designs.

Once the prototype performs well, the same part can be mass-produced for large-scale manufacturing. This process helps companies save time and refine their designs before final production.

Ensuring Product Consistency and Quality

Machine shops maintain high standards of quality. Each piece produced must meet exact specifications. Advanced measuring instruments and quality control systems ensure that every part, whether the first or the thousandth, is identical in quality and performance.

Consistency like this is crucial for industries that produce safety-sensitive items such as car brakes, airplane engines, or medical tools.

Types of Machines Used in a Machine Shop

To perform these tasks, machine shops use a wide variety of machines, each designed for a specific purpose. Let’s look at some of the most common ones:

Lathe Machine

A lathe machine is used to rotate the material while cutting tools shape it. It’s perfect for creating round or cylindrical parts like rods, bolts, and shafts.

Milling Machine

A milling machine uses rotating blades to remove material from a solid block. It can create flat surfaces, holes, and complex shapes needed for mechanical components.

Drilling Machine

The drilling machine is used to make holes of different sizes and depths in materials like metal or plastic.

Grinding Machine

A grinding machine smooths surfaces and ensures that each part has a fine finish. It’s also used to make parts that fit together very tightly.

CNC Machines

Modern machine shops rely heavily on CNC machines (Computer Numerical Control). These machines are controlled by computer programs that follow digital designs with extreme precision. CNC technology makes it possible to create highly complex parts quickly and accurately.

How Machine Shops Help Different Manufacturing Sectors

Machine shops are not limited to one type of work. They serve many different industries, each with its own special requirements.

Automotive Industry

In the automotive industry, machine shops make engine blocks, pistons, gears, and other small mechanical parts. They also help in customizing and repairing old parts to extend vehicle life.

Aerospace Industry

The aerospace sector needs lightweight yet strong parts that can withstand high pressure and temperature. Machine shops create precision components like turbine blades and landing gear parts with the highest safety standards.

Oil and Gas Industry

For oil and gas operations, machine shops produce heavy-duty parts used in drilling, pumping, and refining equipment. The parts must handle extreme conditions and pressure.

Construction and Heavy Equipment

Machine shops manufacture essential components for cranes, bulldozers, and excavators. They also repair worn-out parts, helping companies maintain their machines at lower costs.

Medical Equipment Manufacturing

In the medical field, accuracy and cleanliness are extremely important. Machine shops create small and precise parts used in surgical tools, implants, and diagnostic devices.

The Benefits of Partnering with a Professional Machine Shop

Working with a professional and well-equipped machine shop offers several advantages to manufacturers.

Cost Efficiency

By outsourcing machining work, companies save money on expensive machinery and maintenance. They can get custom parts made when needed without investing in specialized equipment.

Faster Production

Machine shops use advanced machinery that can perform multiple operations at once. This speeds up the entire manufacturing process and ensures on-time delivery.

Quality Assurance

Professional machine shops follow strict quality checks to ensure every part meets required specifications. This guarantees reliability and safety in the final product.

Customization Flexibility

A skilled machine shop can create parts of any shape, size, or design. This flexibility helps manufacturers develop new and innovative products.

The Role of Technology in Modern Machine Shops

Technology has completely transformed how machine shops operate. Today’s shops are more automated, accurate, and efficient than ever before.

CNC Machining

CNC machining is one of the biggest innovations in this field. It allows machines to follow computer-based designs with pinpoint accuracy. Once programmed, a CNC machine can produce hundreds of identical parts without any variation.

3D Modeling and CAD Software

Computer-Aided Design (CAD) software helps engineers design complex parts digitally before production. These digital models are then sent to CNC machines for precise manufacturing.

Automation and Robotics

Some modern machine shops use robotic arms for handling materials and performing repetitive tasks. This improves efficiency, reduces errors, and increases worker safety.

Quality Control Technology

Machine shops use laser scanners, digital measuring tools, and coordinate measuring machines (CMMs) to ensure that every part is made exactly as designed.

The Importance of Skilled Workers in a Machine Shop

While technology plays a big role, skilled human workers are still the heart of every machine shop.

Machinists, engineers, and technicians are responsible for setting up machines, reading blueprints, programming CNC systems, and checking finished parts for quality.

They have the knowledge to adjust tools, materials, and machine speeds to get the best results. Without experienced machinists, even the most advanced machine cannot deliver perfect results.

Training and continuous learning are very important in this field because technology keeps changing. Skilled workers must keep updating their knowledge to operate new systems effectively.

Challenges Faced by Machine Shops

Even though machine shops play such an important role, they also face challenges in their daily operations.

High Equipment Costs

Modern machines and software require heavy investment. Maintenance and updates add to the cost.

Skilled Labor Shortage

Many industries struggle to find skilled machinists who can operate advanced CNC machines and understand complex designs.

Meeting Tight Deadlines

Manufacturers often require parts urgently to keep production running. Machine shops must balance speed with precision to deliver on time without compromising quality.

The Future of Machine Shops in Manufacturing

The future of machine shops looks bright and exciting. As technology continues to advance, machine shops will become even more efficient and versatile.

Automation, artificial intelligence, and digital manufacturing will help reduce human error and speed up production. Smart machines will be able to monitor their performance and adjust automatically for better results.

Sustainability will also become a key focus. Modern machine shops are adopting eco-friendly practices by recycling materials, reducing waste, and using energy-efficient equipment.

Final Thoughts

A machine shop is much more than a workshop — it’s the heart of modern manufacturing. It supports every stage of production, from design to delivery, by creating accurate and durable parts.

Whether it’s building a car engine, repairing industrial machinery, or crafting parts for airplanes, machine shops ensure that industries continue to function smoothly.

Their combination of skilled workers, advanced machines, and modern technology helps bring innovation to life. Without machine shops, the manufacturing industry simply couldn’t exist as it does today.

They keep the wheels of progress turning — one perfectly shaped part at a time.

For more insightful articles related to this topic, feel free to visit : craneflower.net