In an era where maximising both efficiency and durability is crucial across industries, thermal spray coatings present a sophisticated solution that not only extends the life of equipment but also significantly enhances its performance. Understanding the cost-benefit analysis of this technology is key to making informed decisions regarding its adoption.

Let’s delve into when investing in thermal spray coating services truly makes sense from a financial standpoint.

What Are Thermal Spray Coatings?

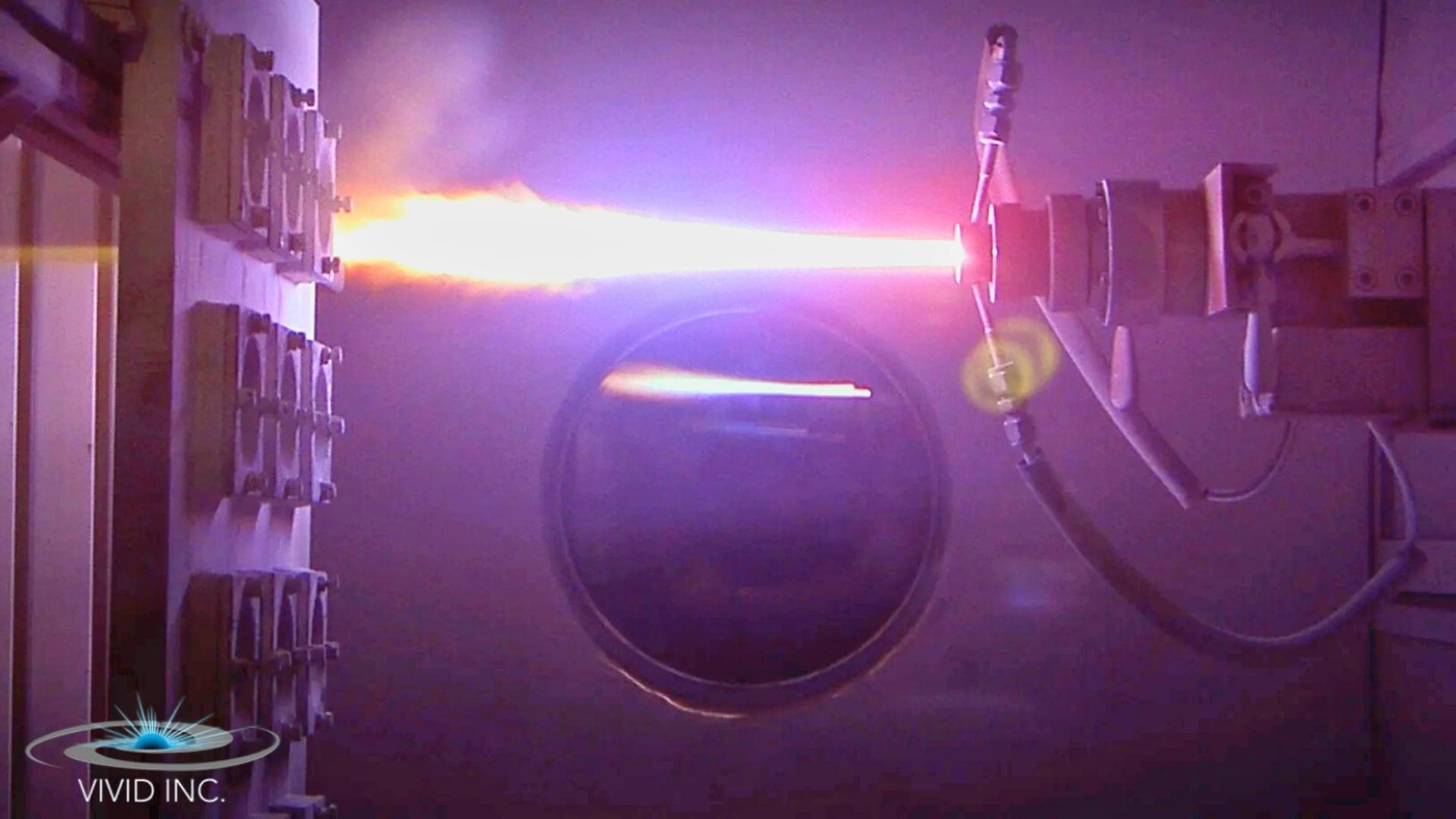

Thermal spray coatings involve the application of a coating material, such as metals, alloys, ceramics, or plastics, to a surface in a molten or semi-molten form. The process uses a heat source to melt a consumable coating material, which is then atomised and sprayed onto a substrate, creating a strong bond and a protective layer on the surface.

The Cost Side

The initial cost of applying thermal spray coatings might be higher than traditional coating methods. This includes the cost of the coating material, which varies depending on the type (metals, ceramics, etc.), and the specific technology and equipment used for the application (plasma spray, HVOF, arc spray, etc.). Additionally, the necessity for specialised knowledge and training for operators can add to the initial investment.

Initial Costs Include:

- Material Costs: Depending on the selected coating material.

- Equipment Costs: Initial investment in thermal spray technology.

- Labour Costs: Training and operation by skilled technicians.

The Benefit Side

- Enhanced Durability and Longevity

Thermal spray coatings are known for their ability to improve wear resistance, reduce corrosion, and protect against high temperatures, significantly extending the life of the treated equipment or components. This means reduced maintenance costs and less frequent replacements, contributing to substantial cost savings over time.

- Increased Efficiency

By protecting against wear and environmental factors, these coatings ensure that machinery operates at peak efficiency, minimising energy consumption and downtime due to repairs. This aspect is particularly beneficial in industries where equipment downtime leads to significant financial losses.

- Versatility Across Industries

Thermal spray coatings are not confined to a single industry but find application across aerospace, automotive, healthcare, energy, and more. Each sector can tailor the coatings to meet specific operational challenges, making this a versatile investment.

Cost-Benefit Scenarios Where Investment Makes Sense

- High Wear Environments

In industries where equipment is subject to extreme wear and tear, the longevity provided by thermal spray coatings can significantly reduce the frequency of repairs and replacements, making the initial investment worthwhile.

- Corrosive Conditions

In situations where corrosion significantly impacts equipment life and performance, the protective barrier offered by thermal spray coatings can afford substantial savings over time, offsetting the upfront costs.

- Regulatory Compliance

For industries subject to strict regulations related to safety and environmental impact, thermal spray coatings offer a means to comply with these requirements without recurring expenditures.

- When Performance is Critical

In sectors where even minor performance improvements can lead to substantial revenue increases (such as in aerospace or high-performance automotive applications), the efficiency gains provided by thermal spray coatings justify the investment.

Conclusion:

While the initial costs associated with thermal spray coatings can be higher than traditional treatments, the long-term benefits—ranging from extended equipment life, reduced maintenance costs, enhanced performance, to regulatory compliance—make it a worthwhile investment for many businesses. A thorough cost-benefit analysis, considering specific operational needs and environmental factors, is essential to determining when the adoption of thermal spray coatings makes the most sense financially.

By carefully assessing the potential savings and performance enhancements against the initial investment and ongoing costs, businesses can make an informed decision on incorporating thermal spray coatings or whether they are seeking arc spray coating into their maintenance and production strategies, ensuring a high return on investment in the long run.