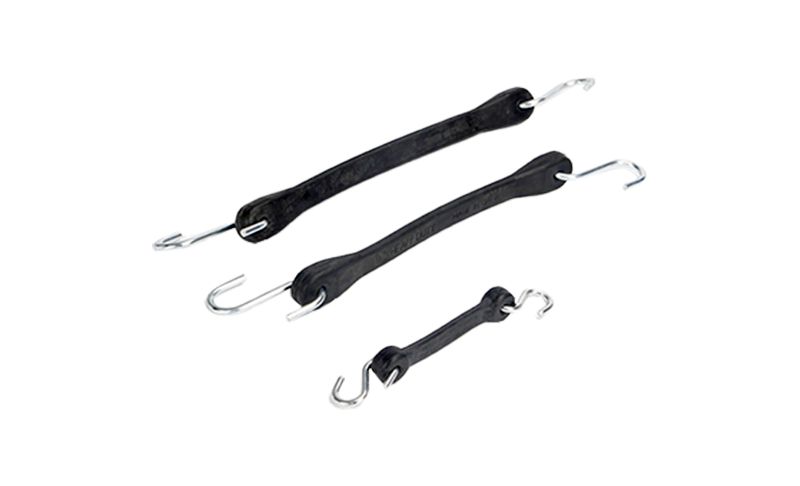

Proper care ensures that EPDM Rubber Tie Down Tarp Straps deliver peak performance through scorching summers, freezing winters, and everything in between. Follow this year-round maintenance guide to maximize service life and safety.

Spring: After harsh winter runs, inspect each set of EPDM Rubber Tie Down Tarp Straps for nicks, cuts, or embedded road debris. A mild solution of dish soap and warm water removes salt residue that can migrate into micro-abrasions and gradually weaken the EPDM matrix. Once clean, allow EPDM Rubber Tie Down Tarp Straps to air-dry away from direct sunlight to prevent premature UV exposure.

Summer: High ambient temperatures accelerate UV degradation in lesser materials, but EPDM Rubber Tie Down Tarp Straps are specifically engineered to resist ozone cracking. Still, storing them in a shaded toolbox or cab compartment during off-duty hours extends longevity. If straps become caked with dust, a quick rinse keeps hooks free of grit that could scratch trailer rails or pickup beds.

Autumn: Leaf season brings acidic tannins and sap that can coat gear. Wipe EPDM Rubber Tie Down Tarp Straps with a silicone-based spray to create a protective film that repels moisture and organic acids. Check hook gates at this time; a drop of light machine oil ensures smooth operation when temperatures plummet.

Winter: The biggest threat to any tie-down is brittleness induced by cold. Fortunately, EPDM Rubber Tie Down Tarp Straps remain flexible down to −40 °F. Nevertheless, avoid overstretching frozen straps immediately after removing them from an unheated trailer box. Instead, bring EPDM Rubber Tie Down Tarp Straps indoors for five minutes so the rubber warms slightly before first use.

Monthly Deep-Clean: Every 30 days, soak EPDM Rubber Tie Down Tarp Straps in a bucket of warm water mixed with a tablespoon of baking soda. This neutralizes acids and lifts embedded grime from the rubber pores. Rinse thoroughly and hang vertically to dry, preventing hooks from banging against walls and chipping galvanization.

Hook Inspection: Pay close attention to the crimped connection between strap and hook. Any sign of separation mandates immediate retirement of that EPDM Rubber Tie Down Tarp Straps unit. Remember, a 25-cent hook failure can trigger thousands in cargo damage.

Storage Best Practices: Coil EPDM Rubber Tie Down Tarp Straps loosely rather than wrapping them tightly around objects. Tight coils create stress points that accelerate fatigue. A mesh storage bag allows airflow while keeping sets organized. Label bags by length so you can quickly grab the correct EPDM Rubber Tie Down Tarp Straps without trial-and-error stretching.

End-of-Life Disposal: When EPDM Rubber Tie Down Tarp Straps finally lose elasticity, dispose of them responsibly. EPDM is recyclable into playground surfacing and automotive seals. Many truck stops now host collection bins dedicated to used EPDM Rubber Tie Down Tarp Straps.

By integrating these simple habits into your routine, your EPDM Rubber Tie Down Tarp Straps will remain trustworthy partners season after season. Invest a few minutes each month, and your EPDM Rubber Tie Down Tarp Straps will repay you with years of safe, reliable service.